What defines a high quality septic system?

by Brady Rettkowski

Over the years, I have always been driven to construct the highest quality septic systems. We are only given a short time on this planet. If something is worth doing, it's worth doing right.

Many years ago, as new drain field technologies became available, I was eager to implement them into my septic systems. The manufacturers of these technologies promised greater performance while also decreasing the necessary labor during construction. I was pleased to experience a considerable increase in production while being able to pass a significant labor savings onto my clientele. I later learned, the manufacturer's promise of greater performance would not be realized. These new technologies presented unexpected problems several years after construction. These alternative technologies were sophisticated attempts to replace the tried and true rock-and-pipe drain fields that had been used reliably, day in and day out, for more than a hundred years. The science of these new technologies made sense, but their actual performance fell short. The unexpected failure rate of the alternative drain field systems started out low, but has steadily increased as the years went on. While others may have an 'acceptable' failure rate concerning their work, I do not. I have always expected a properly cared for septic system to last at least 25 years, in our local soils. When I saw that wasn't happening, I gave up the labor saving alternatives, and went back to constructing rock-and-pipe drain fields, for life.

For me, no amount of profit can justify compromising the quality of my septic systems. Given what I know now, there is no reliable alternative to the rock-and-pipe drain field. My clientele rely on the essential service of my septic systems throughout their daily lives. The importance of this should not be dismissed.

I believe, one of my important missions, is to place my septic systems with well-educated septic system owners. This begins with educating them about materials and construction methods. Some septic systems do meet the standard of high quality, but today sadly, many don't. There are a lot of different ways to construct a septic system and still meet a minimum state approval. You deserve to know, specifically, what products are being used in your septic system project. Consider the source, if someone tries selling you an alternative product that's 'State Approved'. The person pushing this cheaper, alternative product, won't be forced to live with the result, long after they've been paid.

Since March of 1997, I have earned my living by designing, constructing, and repairing septic systems. In the course of learning what works, I've also gotten to see most everything that doesn't. I have seen a lot of failing septic systems. Failures are usually caused by several factors working together. Sometimes failures are caused by the selection of materials used in the project. Sometimes failures are caused entirely by a single factor outside the control of the installer. Listed below, are the materials I require in a basic high quality gravity-operated septic system.

Requirements

The first thing required in a high quality septic system is a properly sized concrete septic tank. The septic tank should be sized to hold at least twice the peak daily flow, based on the system design parameters. The concrete tank should have a vertical riser placing at least one lid at the ground surface. I have seen countless collapsed and dangerous plastic and steel septic tanks. No one plans to drive a loaded mixer truck over their septic tank, but it still happens. Modern concrete tanks, with modern plastic pipes and fittings, will usually outlast several owners and even a couple of drain fields.

The next thing required are concrete drop boxes or distribution boxes, as required. Often times, I see septic system installers cutting costs and labor by installing lightweight plastic boxes. Better than half of the plastic boxes I have ever dug up, are split open between the pipe openings and bottom of the box. It is not uncommon to find collapsed plastic lids and sidewalls on these boxes as well.

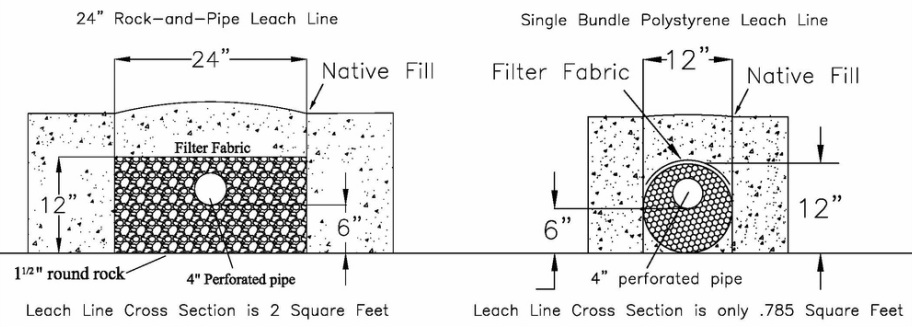

The most important component of a high quality septic system is the rock-and-pipe style drain field (or leach lines). There are several, lower quality, alternative drain field products in use today. The two most common styles are hollow plastic chambers with slots along the sidewalls, and bundles of polystyrene foam peanuts bundled in netting around a perforated pipe. I have constructed septic systems utilizing each of these alternative styles. I can tell you from my experience, neither style can match the performance of rock-and-pipe. Neither will handle the traffic load that rock-and-pipe trenches are capable of, and neither are the volumetric equivalent to rock-and-pipe.

Despite the fact that there is no comparison in performance, both leach line styles are Oregon approved.

You have the choice. Would you prefer to have rock or packing peanuts serving your home?

Here are some problems I've experienced with alternative drain field products.